Product specifications

High performance silicon carbide ceramic heat exchanger possess high strength, high temperature resistance, high thermal conductivity and excellent acid or alkali corrosion resistance. It is mainly used in electric power, iron and steel, metallurgy, chemical, pharmaceutical, textile and other industrial fields. It is especially suitable for the harsh working conditions such as high temperature, high pressure, acid and alkali corrosion, high speed airflow, particle abrasion and etc. The outstanding heat exchanging efficiency provided it with a brilliant performance to meet the urgent needs of Energy saving emission reduction and environmental protection.

Product Description

Silicon carbide ceramics, the best choice of heat exchanging application in the extreme environment

Hilicon carbide is a single phase, pressureless sintered silicon carbide which has high purity, fine grain and low porosity and etc. The silicon carbide ceramic heat exchange parts provided by can be used as an excellent substitute for graphite, stainless steel, tantalum, hastelloy, fluoroplastics and other traditional material parts. In the industry such as chemical engineering, pharmaceutical and metallurgy that have high temperature, high pressure, high corrosion and high abrasion such extreme conditions, silicon carbide ceramic is the best choice and inevitable trend.

Application Fieids

⒈Pharmaceutical Industry

⒉Fine Chemical Industry

⒊Chemical Engineering

⒋Metallurgy Industry

Application Environment

Bromine, sulfuric acid, hydrofluoric acid, nitric acid, hydrochloric acid,etc.

Sodium hydroxide and other alkali

Halogenated compound

Salt solution and organic compounds

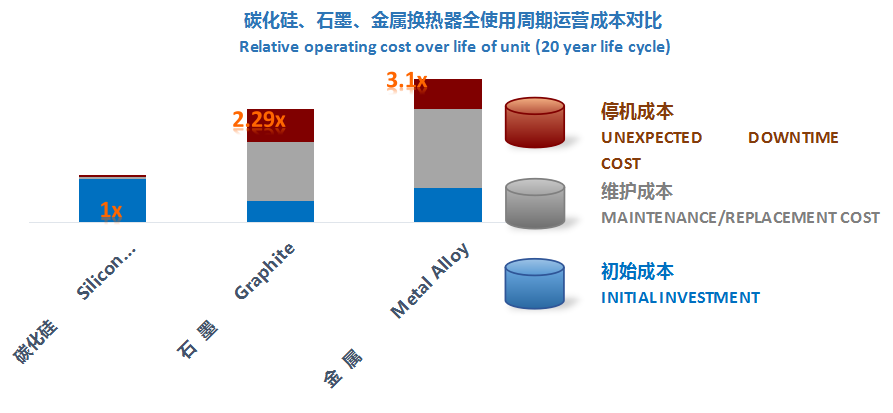

Low Comprehensive Cost

The comprehensive cost is better than graphite, metal heat exchanger

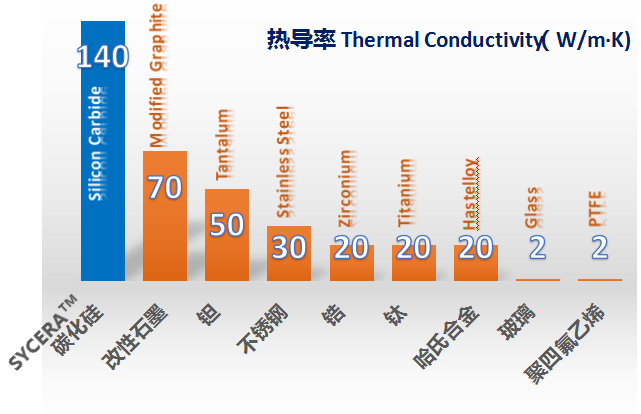

High Thermal Conductivity

• Much higher thermal conductivity than other

• corrosion resistant material

• Less space and smaller size

• Lower cost

Outstanding Corrosion Resistance

• High performance of corrosion, oxidation and erosion resistance

• Endure high concentration of sulfuric acid, nitric acid, phosphoric acid, mixed acid, alkali, and oxidant

• The only hydrofluoric acid corrosion resistant ceramic material

• Long working life

|

Corrosive Medium |

Temp(℃) | Corrosion Rate (mg/cm2•Y) |

| 98% H2SO4 | 100 | 0.98 |

| 54% HF | 25 | 0.06 |

| 50% NaOH | 100 | 1.25 |

| 45% KOH | 100 | 0.04 |

| 70% HNO3 | 86 | 0.04 |

| 37% HCl | 25 | 0.07 |

| 10% HF & HNO3 | 25 | 0.05 |

| 10% HF & HNO3 | 120 | 1.25 |

Excellent Thermal & Mechanical Properties

• High strength and high hardness

• Keep the superior abrasion resistance and anti-permeability in extreme high temperature and high pressure case

• Allow medium pass through with high speed

• Available in the high temperature reached 1300℃

| Test Items | Test Results |

| Bulk Density | 3.12 g/cm |

| Bending Strength | 400 MPa |

| Anti Static Strength | 20 MPa |

| Elastic Modulus | 410 GPa |

| Fracture Toughness | 3.80 MPa●m1/2 |

| Thermal Conductivity | 140 W/m●K |

| Thermal Expansion Coefficient | 4.66(RT-1000oC)10-6/K |

Health Safety Environment

⒈No pollution to the medium in the strong corrosion working condition

⒉Meet the demanding standards for pharmaceutical and food industry